2026 Best Horizontal Screw Conveyor Options and Benefits?

In the world of material handling, the horizontal screw conveyor stands out as an essential piece of equipment. Industry expert Dr. Emily Carter once said, "The effectiveness of a horizontal screw conveyor lies in its design and application." This highlights its crucial role in numerous industries, from agriculture to manufacturing.

Horizontal screw conveyors transport bulk materials efficiently. They work by rotating a helical screw within a trough. This movement allows for a continuous flow of materials, but not without challenges. Proper design and maintenance are vital to avoid common issues like blockages. These can drastically reduce productivity and result in costly downtime.

Choosing the right horizontal screw conveyor is critical. Factors such as material type, transportation distance, and desired capacity can affect performance. However, it's important to reflect on the balance between costs and benefits. While some options may seem appealing, they may not always deliver the expected efficiency. Careful consideration is necessary for optimal outcomes.

2026 Horizontal Screw Conveyor Market Overview and Trends

The horizontal screw conveyor market is evolving, driven by technological advancements. Industries now seek smarter solutions for material handling. Features like enhanced efficiency and space-saving designs are in high demand. Modern conveyors can manage diverse materials, from grains to powders. Moreover, their adaptability sets them apart in various sectors.

Tips: Focus on the specific materials you handle. This can affect the conveyor's design. Always consider the available space for installation. Measurements matter!

The focus on sustainability is also rising. Manufacturers are exploring eco-friendly materials and energy-efficient designs. This trend reflects broader ecological concerns. However, some systems still struggle with energy consumption. A balance between efficiency and sustainability is important.

Tips: Regular maintenance is key. It ensures optimal performance and longevity. Consider training staff to identify early signs of wear and tear. This proactive approach can prevent major issues.

Key Features and Innovations of Horizontal Screw Conveyors in 2026

Horizontal screw conveyors have evolved significantly in 2026. The latest designs focus on efficiency and reliability. Enhanced materials are being utilized to withstand abrasive materials, making the conveyors last longer. Innovations in motor technology offer better energy efficiency, which is crucial in various industries.

Another notable feature is the integration of smart technology. Sensors are now common, providing real-time data on performance. This allows for proactive maintenance, reducing downtime. However, some users may find the initial costs a bit high. Balancing investment with long-term savings can be challenging. The complexity of some systems may require specialized training for operators, adding another layer of consideration for businesses.

Ultimately, the advancements in horizontal screw conveyors highlight a need for customization. One size doesn’t fit all in material handling. Companies must assess their specific needs before adopting new technologies. Ignoring these variables could lead to inefficiencies in the long run. As innovation continues, the industry's landscape will transform, requiring constant reflection on operational strategies.

2026 Best Horizontal Screw Conveyor Options and Benefits

This chart highlights key features of horizontal screw conveyors in 2026, including durability, efficiency, cost, maintenance, and versatility, rated on a scale from 1 to 10. The data reflects the importance of these features for optimal performance and user satisfaction.

Benefits of Using Horizontal Screw Conveyors for Bulk Material Handling

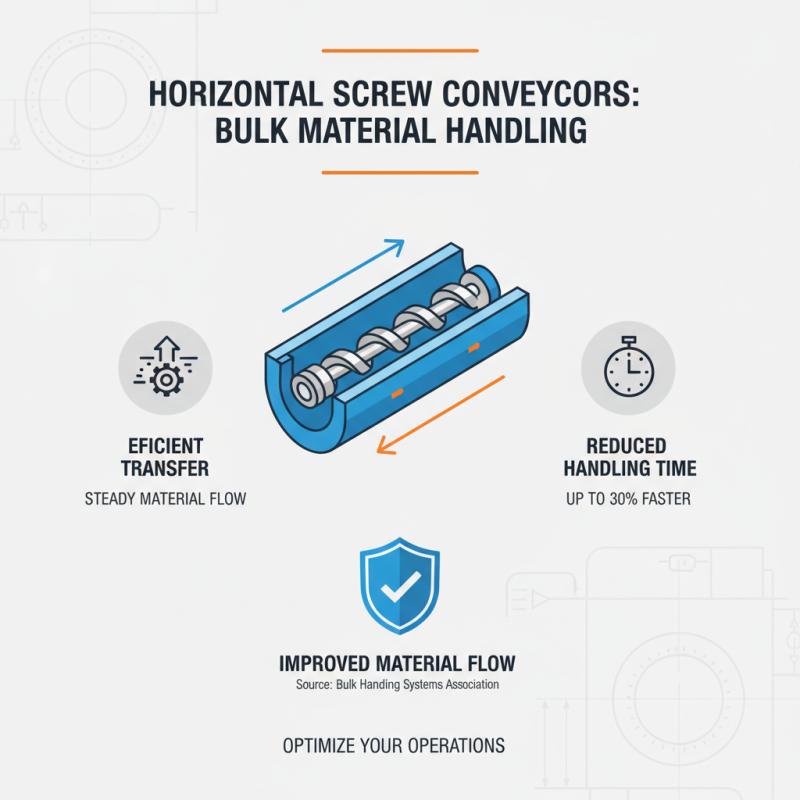

Horizontal screw conveyors provide efficient solutions for bulk material handling. Their design allows for the steady transfer of materials over various distances. According to a report from the Bulk Handling Systems Association, these conveyors can improve material flow by up to 30%, significantly reducing handling times.

One of the key benefits is their adaptability. Industries use them to transport powdery and granular materials. The flexibility of installation angles enhances their efficiency in tight spaces. However, the wear and tear on the screws can lead to maintenance challenges. Users often overlook this, impacting long-term productivity. Regular inspections can mitigate unexpected downtime.

Moreover, horizontal screw conveyors can handle diverse materials, from food products to chemicals. This versatility is valuable. However, it's crucial to consider material compatibility. Some materials may cause corrosion or sticking. Ignoring these factors can lead to inefficiencies. Thus, understanding the material characteristics is essential for optimal performance.

Comparative Analysis of Leading Horizontal Screw Conveyor Manufacturers

When evaluating horizontal screw conveyors, examining leading manufacturers offers insights into design and technology trends. These conveyors are essential for efficient bulk material handling. They operate on a simple principle—the helical screw moves materials along a trough. However, the design can vary significantly between manufacturers.

Some manufacturers focus on modular designs that allow for easy maintenance and replacement. Their products often feature advanced materials to enhance durability. Others might prioritize energy efficiency, integrating motors and controls that optimize power usage. Yet, there are concerns around performance consistency. Some conveyors may show variations in throughput.

User feedback often highlights the importance of after-sales service. A manufacturer that offers solid support can make a significant difference. While some options may exhibit impressive specs, longevity and serviceability are critical. Innovations in material science can improve performance, but often the basics of customer service remain paramount for successful operation.

Efficiency Metrics: Performance Data for Horizontal Screw Conveyors

Horizontal screw conveyors are vital in many industries. They efficiently transport bulk materials. Performance data indicates that these conveyors can achieve high throughput rates. For instance, capacities often range from 30 to 1,500 tons per hour. This capacity varies based on materials and design.

Efficiency metrics play a crucial role in assessing performance. Factors like energy consumption, wear and tear, and maintenance frequency matter. Some conveyors may consume more energy than others. This can lead to higher operational costs. Regular maintenance can mitigate these issues, but the costs can accumulate.

It’s essential to consider the application. Not all screw conveyors are perfect for every situation. Performance may differ based on material characteristics like density and moisture content. Users should evaluate their specific needs carefully. Sometimes, the best option may not be the most efficient. Understanding these details can lead to better choices.

Related Posts

-

2025 How to Choose the Right Screw Conveyor Auger for Your Needs

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One

-

Top 10 Belt Conveyors Trends to Watch in 2025 for Efficient Material Handling

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

How to Choose the Best Industrial Food Grinder Machine for Your Business