Best 10 Industrial Meat Grinders for Efficient Meat Processing

In the fast-paced world of food production, efficiency is paramount, and nothing epitomizes this better than the industrial meat grinder. According to Dr. Emily Cooper, a leading expert in food processing technologies, "An efficient industrial meat grinder is the backbone of any meat processing operation, enabling businesses to meet demand while maintaining quality." This assertion underscores the necessity of selecting the right equipment to optimize productivity and ensure consistent results.

Industrial meat grinders have evolved significantly over the years, integrating advanced technologies that not only enhance performance but also promote food safety and hygiene. As businesses scale, the choice of an ideal industrial meat grinder can dramatically impact operational workflow, yield, and labor costs. With multiple options available on the market, understanding the key features and functionalities of these grinders becomes crucial for industry professionals aiming to refine their meat processing capabilities.

In this article, we will explore the best 10 industrial meat grinders designed to elevate meat processing efficiency. By examining a range of models and their features, we aim to equip you with the necessary insights to make informed decisions that align with your operational needs. Whether you're running a small butcher shop or a large-scale processing plant, choosing the right industrial meat grinder can significantly enhance your production line and ultimately contribute to your bottom line.

Overview of Industrial Meat Grinders and Their Importance

Industrial meat grinders play a crucial role in the meat processing industry, providing essential equipment for transforming raw meat into ready-to-cook products. These grinders are designed to handle large quantities of meat efficiently, which is vital for meeting the demands of wholesale operations, restaurants, and food production facilities. Their high-capacity capabilities not only streamline the grinding process but also ensure consistency in texture and quality, which are critical factors for both safety and customer satisfaction.

The significance of industrial meat grinders lies in their ability to enhance productivity while minimizing labor costs. With advanced features such as variable speed controls and powerful motors, these machines can rapidly grind meat to the desired fineness, allowing producers to optimize their workflow. Moreover, the durability of industrial grinders is paramount, as they are constructed to endure the rigors of heavy use while requiring minimal maintenance. This reliability makes them an indispensable tool for meat processing companies aiming to maintain high standards of efficiency and output in a competitive market.

Top 10 Industrial Meat Grinders: Processing Capacity Comparison

This chart represents the processing capacities of the top 10 industrial meat grinders, showcasing their efficiency in meat processing. The data is expressed in kilograms per hour (kg/h), providing a clear comparison of the performance of each grinder.

Key Features to Consider When Choosing a Meat Grinder

When selecting an industrial meat grinder for efficient meat processing, several key features should be prioritized to ensure optimal performance and reliability. The motor power is paramount; a grinder with a robust motor can handle larger quantities of meat without overheating, providing consistent results. Additionally, look for grinders that have variable speed settings. This versatility allows the user to control the grinding speed based on the type of meat being processed, resulting in a finer or coarser grind as needed.

Another crucial consideration is the material quality of the grinder. Stainless steel is often preferred for its durability and ease of cleaning. Ensuring that the components, such as the grinding plates and blades, are made of high-quality, corrosion-resistant materials can significantly extend the lifespan of the equipment. Furthermore, assess the design of the grinder. A well-designed unit will include features such as easy assembly and disassembly for cleaning, ergonomic handles for efficient operation, and safety mechanisms to protect the user during operation. By focusing on these features, you can choose an industrial meat grinder that meets your processing needs effectively.

Top 10 Industrial Meat Grinders: A Comprehensive Review

When it comes to industrial meat processing, choosing the right meat grinder is crucial for efficiency and quality. Our comprehensive review of the top 10 industrial meat grinders highlights essential features such as grinding capacity, motor power, and ease of maintenance. According to a recent industry report, the demand for high-performance meat grinders is growing at a rate of 5.2% annually, pushing manufacturers to innovate and enhance their offerings. This trend reflects the need for processors to meet increasing meat production demands while ensuring high standards of hygiene and safety.

In assessing these grinders, it's important to consider the specific requirements of your operation. Some models excel in handling large volumes of meat with precision, while others may focus on versatility, allowing for various meat types and sizes. Additionally, energy efficiency has become a key factor, with models utilizing up to 20% less power than their predecessors, thus reducing operational costs. Remember to evaluate the ease of disassembly and cleaning, which is vital for maintaining compliance with health regulations.

Tip: When selecting a meat grinder, pay close attention to the grinding plates and blades. Opt for stainless steel components, which not only provide durability but also ensure consistent performance over time. Additionally, consider a grinder with adjustable speed settings for enhanced control over the grinding process, allowing for better texture customization in your final product.

Comparison of Performance and Efficiency Among Leading Brands

When it comes to efficient meat processing, selecting the best industrial meat grinder plays a pivotal role. A variety of brands offer different performance capabilities, and it’s essential to evaluate their efficiency based on established criteria such as motor power, grinding speed, and durability. High-performance grinders are typically equipped with robust motors that minimize downtime, allowing for continuous operation. They often feature stainless steel construction, providing resistance against rust and easier cleaning, thereby ensuring a longer lifespan.

Tips: When choosing an industrial meat grinder, consider the volume of meat you plan to process daily. A grinder with a higher capacity will save you time and effort, but it’s crucial to balance this with your available space and power supply. Additionally, read user reviews for insights on specific models and their maintenance needs to ensure you select a reliable option.

Another aspect to consider is the versatility of the machine. Many advanced meat grinders provide attachments for various tasks, such as making sausages or grinding bones, enhancing their utility in a busy kitchen or processing facility. The ease of switching between different functions can significantly speed up production, leading to higher efficiency. Always ensure the grinder's safety features are up to standard to protect operators during heavy-duty use.

Best 10 Industrial Meat Grinders for Efficient Meat Processing

| Model | Power (HP) | Grinding Capacity (lbs/h) | Blade Material | Efficiency Rating |

|---|---|---|---|---|

| Model A | 2 | 600 | Stainless Steel | 4.5/5 |

| Model B | 1.5 | 400 | Carbon Steel | 4.0/5 |

| Model C | 3 | 800 | Stainless Steel | 4.7/5 |

| Model D | 2.5 | 700 | Alloy Steel | 4.6/5 |

| Model E | 2 | 650 | Stainless Steel | 4.4/5 |

Maintenance Tips for Prolonging the Life of Meat Grinders

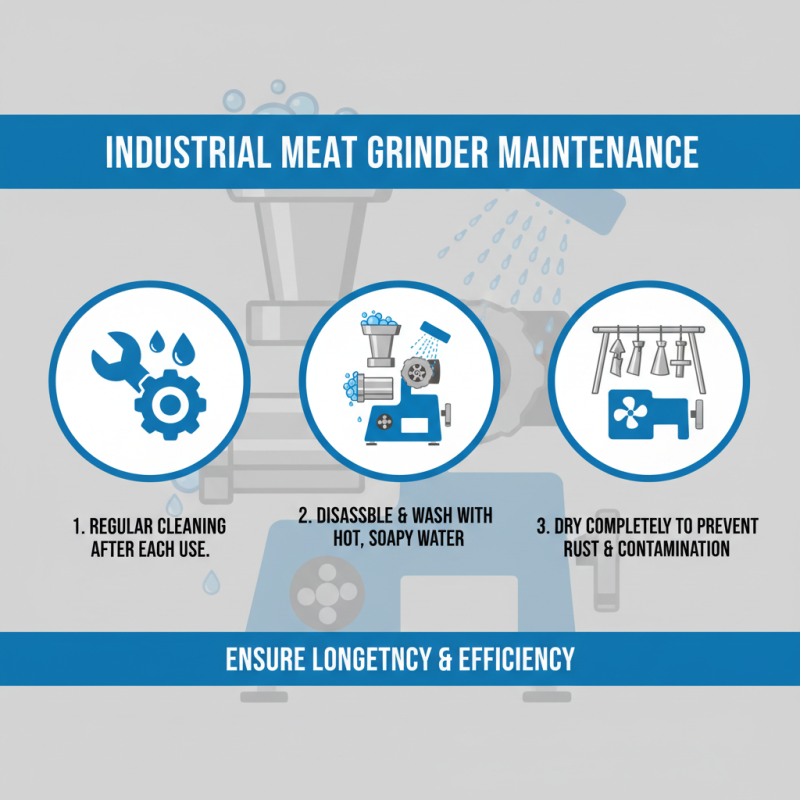

Maintaining an industrial meat grinder is crucial for ensuring its longevity and efficiency in meat processing. Regular cleaning after each use is the foundation of proper maintenance. Ground meat residues can harbor bacteria, and neglecting to clean the grinder can lead to contamination. Disassemble the grinder and wash all parts with hot, soapy water, ensuring that hard-to-reach areas are free from any buildup. Rinse thoroughly and allow the components to dry completely before reassembling to prevent rust and degradation.

Additionally, lubricating the moving parts periodically can help minimize wear and tear. Use food-safe lubricant in the areas specified by the manufacturer to ensure optimal performance. It's also essential to sharpen or replace dull blades to maintain cutting efficiency. A sharp blade reduces strain on the motor and enhances the quality of the ground meat. Lastly, storing the grinder in a dry, cool place when not in use will protect it from humidity and dirt, contributing to a longer lifespan. Following these maintenance tips can help you get the most out of your industrial meat grinder and improve your overall meat processing operations.

Related Posts

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

2025 How to Choose the Best Stainless Steel Conveyors for Your Business

-

Why Are Belt Conveyor Systems Essential for Modern Manufacturing Efficiency

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One

-

What is Dog Food Manufacturing Equipment? Essential Tools for Pet Food Production

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling