Best Metal Detectors for Conveyor Belts to Ensure Product Safety

In today's manufacturing landscape, ensuring product safety is paramount. A metal detector for conveyor belt systems plays a crucial role in achieving this goal. According to industry reports, contamination from metal fragments can lead to severe consequences, not only damaging machinery but also endangering consumer health. In fact, 75% of food recalls in the last year were linked to foreign materials, highlighting the urgent need for effective detection systems.

Metal detectors are essential for various industries, including food processing and pharmaceuticals. These devices can identify ferrous, non-ferrous, and stainless steel contaminants, ensuring that products are safe for consumption. However, many facilities still overlook the integration of reliable metal detection systems. Some opt for manual inspections, which can be inconsistent and ineffective.

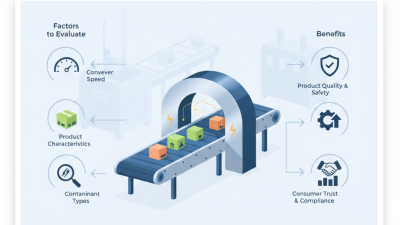

Choosing the right metal detector for conveyor belt applications requires careful consideration. Factors such as sensitivity, installation ease, and maintenance must be assessed. An inadequate system might lead to undetected contamination, resulting in costly recalls. Thus, investing in high-quality detection technology is not just a regulatory necessity; it’s a commitment to quality and safety.

Best Practices for Selecting Metal Detectors for Conveyor Belts

When selecting metal detectors for conveyor belts, various factors demand attention. The environment plays a crucial role. For instance, harsh conditions like extreme temperature or humidity can affect detector performance. Assessing these factors can lead to better equipment choices.

Additionally, conveyor speed can impact detection accuracy. Slower belts allow for more detection time, while faster speeds might require advanced technology.

It’s essential to consider the type of metal you aim to detect. Ferrous and non-ferrous metals behave differently in magnetic fields. Understanding these differences will influence the detector's effectiveness. Often, companies overlook the installation process.

Poor configuration can lead to false negatives. Routine maintenance is another aspect that deserves focus. Regular checks ensure optimal functionality and can prevent costly downtimes.

Operator training is vital but often neglected. Even the best equipment can underperform without knowledgeable staff. This oversight creates potential safety risks. Moreover, it’s worth noting that not all detectors fit every application. Selecting the wrong type can lead to significant oversights. Therefore,

thorough research and a reflective approach are essential.

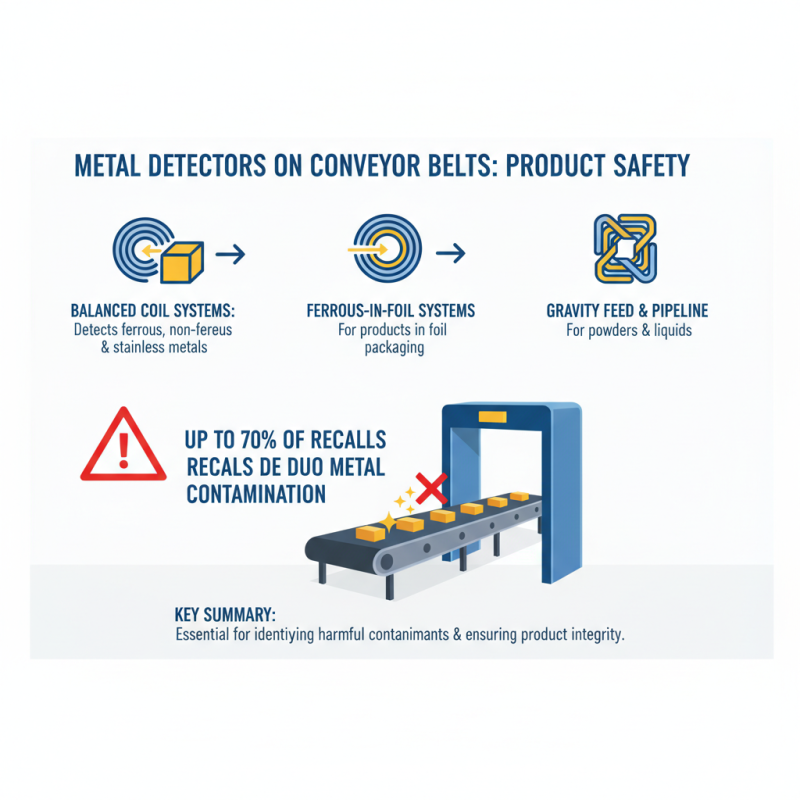

Understanding the Types of Metal Detectors Used in Product Safety

When it comes to ensuring product safety, understanding the types of metal detectors used on conveyor belts is crucial. These detectors play a vital role in identifying harmful metal contaminants that can compromise product integrity. Reports from industry experts indicate that up to 70% of product recalls are related to metal contamination. This statistic highlights the importance of incorporating effective detection systems.

Metal detectors come in various types, including high-sensitivity models and those designed for specific applications. Some detectors use pulse induction technology, making them suitable for challenging product environments. Others might employ balanced coil technology, providing consistent and reliable detection. Each method has its strengths and weaknesses, requiring careful consideration based on your specific needs.

Tip: Regularly test your metal detection systems to ensure they function correctly. Calibration is essential for maintaining accuracy. Another important factor is the placement of the detectors on the conveyor belt. Positioning them correctly can make a significant difference in detection efficiency. Small adjustments can yield better results.

It's worth mentioning that while these systems are highly effective, they are not foolproof. Some contaminants can be missed, leading to potential risks. Investing in employee training on best practices can go a long way in reducing these oversights. Ultimately, a combination of technology and human vigilance is essential for maintaining product safety.

Key Features and Specifications for Conveyor Belt Metal Detectors

When selecting metal detectors for conveyor belts, it's essential to focus on key features. Effective detectors should have multiple sensitivity settings. This allows for flexible detection of various metal types, including ferrous and non-ferrous metals. Consider units with a robust build. A sturdy design helps withstand the rigors of industrial environments.

A reliable conveyor belt metal detector must integrate seamlessly into existing systems. Look for models that offer easy installation and minimal maintenance. These aspects not only save time but also reduce operational costs. The detection speed is also crucial. It should not compromise the flow of products on the conveyor.

Tips: Regularly check the calibration of your metal detector. This ensures consistent performance and accuracy. Also, train staff properly. Proper training improves the efficiency of the detection process. Frequent inspection of the conveyor belt for wear can prevent undetected metal contamination. Take time to analyze detection reports. These insights can highlight potential issues and improve overall product safety.

Industry Standards and Compliance for Metal Detection in Food Safety

Metal detection in food processing is critical for ensuring product safety. Industry standards dictate that food manufacturers should implement robust detection systems. According to a report by the Food Safety and Inspection Service (FSIS), 80% of food recalls are related to contamination issues. Among these, metal contamination poses a significant risk.

For conveyor belts, suitable metal detectors must comply with safety standards. The European Union's food safety legislation requires that all food products be free from harmful contaminants. Detection systems must be capable of identifying ferrous and non-ferrous metals. Many facilities experience difficulties achieving this standard. Regular maintenance and testing are often overlooked. One study noted that 30% of installed systems failed to detect metals consistently during routine inspections.

The choice of metal detectors affects compliance. Many users need to consider false rejection rates, which can disrupt production. The ideal metal detector minimizes false positives while ensuring contamination detection. A balance between productivity and safety is often challenging to achieve. Investing in reliable technology is crucial, but maintenance schedules must also be prioritized.

Best Metal Detectors for Conveyor Belts to Ensure Product Safety

This bar chart illustrates the detection efficiency of various metal detector models used in conveyor belt systems for food safety compliance. Ensuring high detection efficiency is crucial for maintaining product safety standards.

Impact of Metal Contamination on Product Quality and Safety in Manufacturing

Metal contamination is a serious issue in manufacturing. It can greatly affect product quality and safety. Contaminants can come from machinery, tools, or even the environment. When metal particles mix with products, they can lead to severe injury or damage. Companies must take steps to prevent this contamination.

To ensure safety, regular inspections of conveyor belts are essential. Metal detectors play a critical role in identifying contaminants. These detectors can effectively spot even small metal fragments. By using them, manufacturers can safeguard their products before they reach consumers.

**Tips:** Maintain your equipment regularly. A clean conveyor belt reduces risks. Train staff on contamination risks. Awareness is key. Encourage a culture of safety. Employees should know how to react if they find metal debris. This proactive approach minimizes risks and enhances product safety.

Related Posts

-

How to Choose the Right Metal Detector for Your Conveyor Belt System

-

The Ultimate Guide to Dog Food Manufacturing Equipment in 2025 Top Trends

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

2025 Top Commercial Meat Grinders with Industry Leading Performance and Durability

-

How to Choose the Right Dog Food Manufacturing Equipment for Your Business

-

7 Best Metal Detectors for Conveyor Belts to Ensure Quality Control in 2023