How to Choose the Best Commercial Meat Grinder for Your Business Needs

When selecting the best commercial meat grinder for your business, it is essential to understand the unique demands of your operation. A commercial meat grinder is a pivotal piece of equipment that can enhance efficiency, productivity, and the overall quality of your products. With numerous models and features available on the market, making an informed choice is imperative to meet your specific needs, whether you run a restaurant, butcher shop, or food production facility.

The right commercial meat grinder not only ensures that you produce high-quality ground meat but also affects the speed and ease of your daily operations. Factors such as capacity, power, and durability are crucial in determining which grinder will serve your business best. Additionally, ease of cleaning and maintenance should not be overlooked, as these aspects directly impact your workflow and food safety standards.

By taking the time to evaluate your requirements and understanding the different features available, you can effectively navigate the vast options and select a commercial meat grinder that aligns with your business's operational needs. Investing in the right equipment will ultimately lead to better service, improved product offerings, and enhanced customer satisfaction.

Understanding Your Business Requirements for a Meat Grinder

When selecting a commercial meat grinder, it is crucial to first evaluate your specific business requirements to ensure optimal performance and efficiency. Consider the volume of meat you need to process weekly or daily. A high-capacity grinder may be necessary for busy establishments like butcher shops or large restaurants, while smaller operations might be adequately served by a lower capacity model. Understanding the types of meat you commonly process—whether it be beef, pork, poultry, or a mix—will also influence the type of grinder you choose, as different machines are tailored for various textures and fat contents.

Another key aspect to assess is the level of grinding precision your business demands. Some operations may require coarse grinds for products like sausage, while others might need a fine grind for specialty dishes. The versatility of a grinder, including its ability to handle various attachments and accessories, can greatly enhance your production capabilities. Additionally, consider the ease of cleaning and maintenance; a machine that is complicated to disassemble can lead to delays and increased labor costs. By thoughtfully considering these factors, you can select a meat grinder that aligns perfectly with the demands of your business and helps streamline your operations.

Key Features to Look for in a Commercial Meat Grinder

When selecting a commercial meat grinder, it is vital to consider several key features that align with your business needs. First and foremost, the grinding capacity is crucial; businesses requiring high volumes should look for grinders capable of processing anywhere between 300 to 800 pounds of meat per hour. According to the Food Equipment Manufacturers Association, demand for commercial meat processing equipment is expected to grow by 5% annually, underlining the importance of investing in a machine that can handle significant workloads efficiently.

Additionally, the motor power of the grinder is another important factor. A robust motor, typically ranging from 1 to 3 horsepower, ensures consistent and efficient grinding performance, reducing the likelihood of overheating or breakdowns during peak hours. Moreover, ease of cleaning and maintenance should not be overlooked, as grinders with removable components and stainless steel finishes can enhance hygiene and durability. The United States Department of Agriculture also emphasizes the importance of equipment sanitation, noting that effective cleaning practices can prevent contamination and ensure food safety in commercial environments. Thus, careful evaluation of these features can significantly impact the efficiency and safety of meat processing operations.

Types of Commercial Meat Grinders: Which One is Right for You?

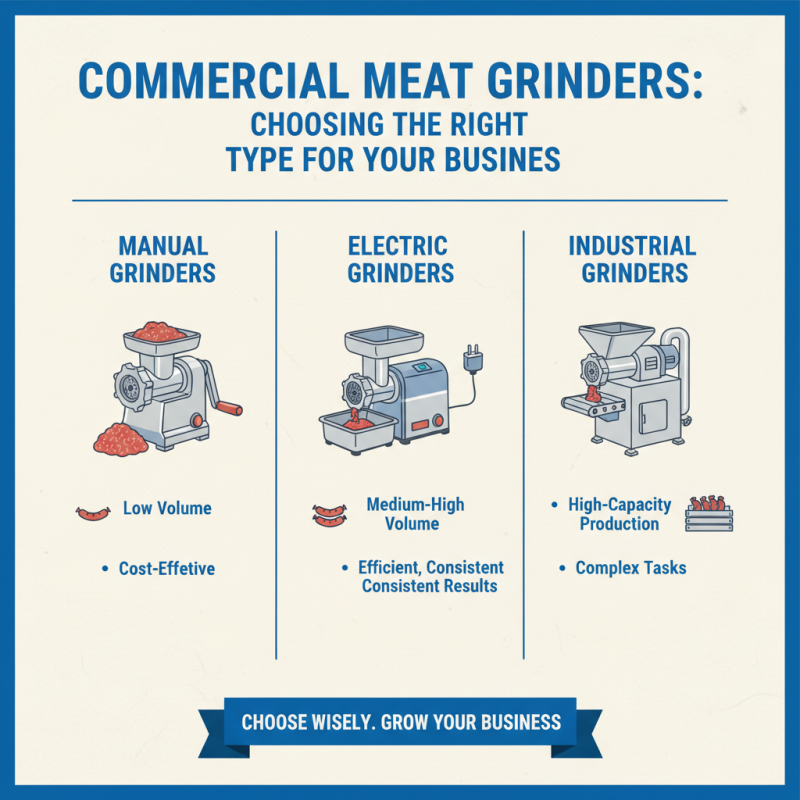

When selecting the best commercial meat grinder for your business, understanding the various types of grinders available is crucial. Broadly, commercial meat grinders can be categorized into three main types: manual, electric, and industrial grinders. Each type serves different needs based on the volume of meat processing and the complexity of the tasks at hand. For example, manual grinders are typically less expensive and suitable for low-volume operations, while electric grinders offer greater efficiency and consistent results, making them ideal for medium to high-capacity demands.

According to a report by IBISWorld, the commercial meat grinder industry has experienced significant growth, with key drivers being the increasing demand in the food service sector and a shift towards in-house meat processing. Electric grinders, which dominate the market, can range from 1 hp for small operations to upwards of 5 hp for larger entities. Additionally, heavy-duty industrial grinders are specifically designed for high output applications, capable of processing hundreds of pounds of meat per hour. Understanding your business's volume requirements and expected output is essential in choosing the right type of grinder to ensure operational efficiency and cost-effectiveness.

Comparing Brands and Models for Performance and Reliability

When selecting a commercial meat grinder, the performance and reliability of different brands and models are crucial factors to consider. According to a recent industry report by IBISWorld, the commercial meat processing equipment market is projected to grow by 3.5% annually, indicating an increasing demand for high-quality meat grinders in various sectors, including restaurants, butcher shops, and food manufacturing. To ensure optimal performance, businesses should look for grinders with robust motor capacities—typically ranging from 1 to 3 horsepower—which can handle different meat types and volumes efficiently.

Reliability is equally important when investing in a meat grinder. A study by the National Association of Meat Purveyors found that equipment downtime can cost businesses an average of $2,500 per day. Therefore, brands that provide durable materials and have a good track record of consistent performance should be prioritized. Features such as stainless steel parts, easy-to-clean designs, and warranty offerings can serve as indicators of reliability. Additionally, user reviews and performance ratings from reputable sources can help businesses make informed decisions by comparing models based on real-life experiences.

How to Choose the Best Commercial Meat Grinder for Your Business Needs - Comparing Brands and Models for Performance and Reliability

| Model | Power (HP) | Grind Capacity (lbs/hr) | Noise Level (dB) | Material | Price ($) |

|---|---|---|---|---|---|

| Model A | 1.5 | 300 | 75 | Stainless Steel | 800 |

| Model B | 2.0 | 400 | 72 | Aluminum | 1200 |

| Model C | 2.5 | 500 | 70 | Stainless Steel | 1500 |

| Model D | 1.0 | 200 | 78 | Plastic | 600 |

Budget Considerations and Cost-Effectiveness in Meat Grinder Selection

When selecting the best commercial meat grinder for your business, budget considerations play a crucial role in ensuring cost-effectiveness. With the meat processing equipment industry projected to grow at a CAGR of approximately 3.4% from 2021 to 2026, understanding the financial implications of your equipment choices is more critical than ever. A key aspect to consider is the initial investment versus the long-term operational costs. High-quality grinders may require a larger upfront expenditure, but their durability and efficiency can lead to significant savings in maintenance and repair costs over time.

In addition, analyzing the specific needs of your operation can help you choose a grinder that optimally balances price and performance. According to a recent industry report, businesses that tailor their equipment choices to match their volume and type of meat processing report up to 20% savings in labor costs due to increased efficiency. For instance, selecting a grinder with a higher RPM can expedite the grinding process, reducing labor hours while also enhancing product consistency. By carefully assessing both the initial costs and the operational efficiencies gained from your meat grinder selection, you can make an informed decision that aligns with your business's financial objectives.

Meat Grinder Price Comparison by Power (in Watts)

Related Posts

-

2025 Top Commercial Meat Grinders with Industry Leading Performance and Durability

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling