How to Choose the Right Industrial Food Equipment for Your Business Needs

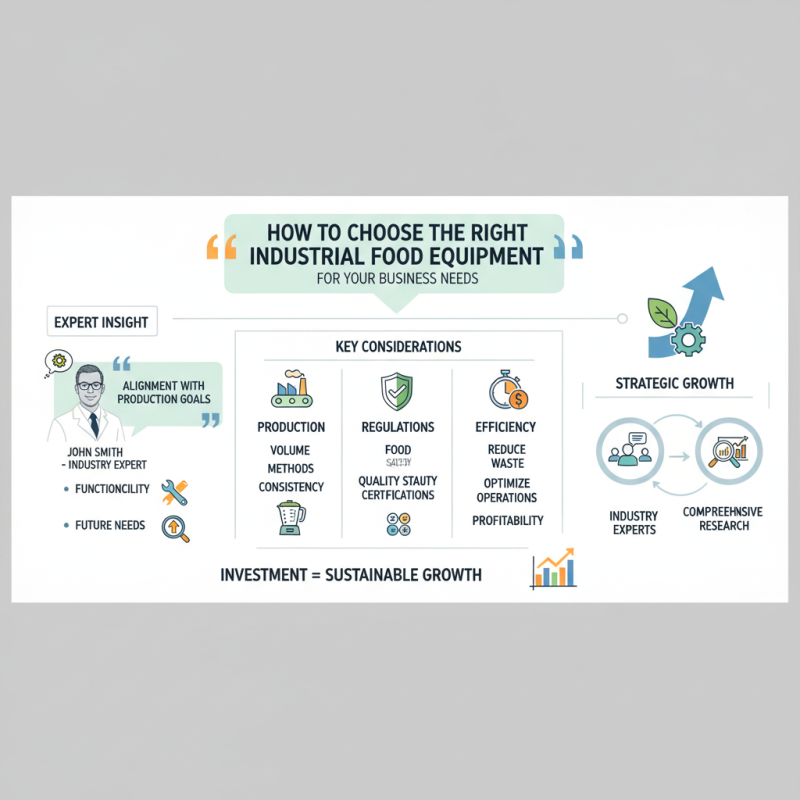

In today's rapidly evolving food industry, selecting the right industrial food equipment is a critical decision that can significantly impact operational efficiency, product quality, and overall business success. According to John Smith, a renowned expert in industrial food processing, "Choosing the right equipment is not just about functionality; it’s about ensuring that every piece of machinery aligns with your overall production goals." His insight underscores the importance of thoroughly evaluating both current and future needs before making a purchase.

As businesses strive to meet the growing demand for food products, understanding the specific requirements of your operation becomes paramount. Factors such as production volume, processing methods, and food safety regulations all play a vital role in determining the most suitable equipment for your company. Properly chosen industrial food equipment can streamline operations, reduce waste, and enhance product consistency, ultimately leading to increased profitability.

Moreover, engaging with industry experts and conducting comprehensive research can provide valuable insights into the latest trends and technologies in food processing. It's essential to recognize that the investment in industrial food equipment is not just an expense, but a strategic move towards achieving sustainable growth and meeting consumer expectations in an increasingly competitive market.

Understanding Your Business Requirements for Food Equipment

When choosing the right industrial food equipment for your business, it's essential to start with a clear understanding of your unique business requirements. Each food establishment has distinct operational needs based on the type of cuisine, volume of production, and service style. For instance, a fast-casual restaurant may prioritize speed and efficiency in food preparation, necessitating equipment that can handle high throughput, while a gourmet kitchen might focus on precision and versatility to craft intricate dishes. Assessing the specific tasks your equipment will need to perform can help you narrow down choices and ensure you invest in tools that genuinely meet your operational demands.

Additionally, consider the scalability of your food equipment. As your business grows, you may find that your initial choices no longer suffice to meet increasing demand. It’s crucial to anticipate future needs and select equipment that can adapt or expand alongside your operations. Whether it’s a larger mixer, additional ovens, or specialized refrigeration, investing in scalable solutions can save you from encountering bottlenecks as business expands. Ultimately, being mindful of your business’s unique requirements—and planning for eventual growth—will position you to make informed decisions that enhance efficiency and productivity.

Evaluating Different Types of Industrial Food Equipment

When evaluating different types of industrial food equipment, it is essential to consider the specific needs of your business.

The type of food being processed—whether it's fresh produce, meats, or baked goods—will dictate the kind of equipment required.

For example, a bakery may need specialized ovens and mixers, while a meat processing facility might require slicers and grinders.

Conducting a thorough analysis of your production processes and understanding how each piece of equipment can enhance efficiency is crucial.

In addition to the type of food, think about the scale of your operations. Smaller businesses may benefit from versatile, multifunctional machines that can perform several tasks,

while larger operations might need heavy-duty machinery designed for high-volume production.

Energy efficiency, ease of maintenance, and compliance with food safety standards are also significant factors to consider.

Ultimately, assessing your production goals and aligning them with the right industrial food equipment will help streamline operations and improve overall productivity.

Key Features to Look for in Food Processing Machinery

When selecting food processing machinery, understanding the key features that align with your business needs is essential for maximizing efficiency and productivity. One critical feature is the machine’s capacity, which should match your production volume requirements. Proper sizing ensures that you can meet demand without bottlenecks or unnecessary downtime. Additionally, consider the machine’s adaptability. Equipment that can handle various product types or sizes provides flexibility as your business evolves and customer preferences change.

Another important aspect to evaluate is the ease of cleaning and maintenance. Hygiene is paramount in the food industry, so choosing machinery designed for easier cleaning can save time and uphold safety standards. Look for features like smooth surfaces, accessible components, and removable parts. Finally, energy efficiency is a vital consideration; machinery that consumes less energy not only reduces operational costs but also contributes to sustainability efforts. By prioritizing these features, you can make an informed decision that best supports your food processing objectives.

How to Choose the Right Industrial Food Equipment for Your Business Needs

| Feature | Importance | Considerations |

|---|---|---|

| Durability | Ensures long-term usage | Material quality and resistance to wear |

| Energy Efficiency | Reduces operating costs | Look for energy ratings and consumption data |

| Ease of Cleaning | Maintains hygiene standards | Check for smooth surfaces and accessibility |

| Capacity | Affects production volume | Match with your business scale |

| Compliance with Regulations | Ensures safety and legality | Check local and international standards |

| Technology Integration | Enhances efficiency and oversight | Look for IoT compatibility or automation options |

Budgeting for Your Industrial Food Equipment Purchase

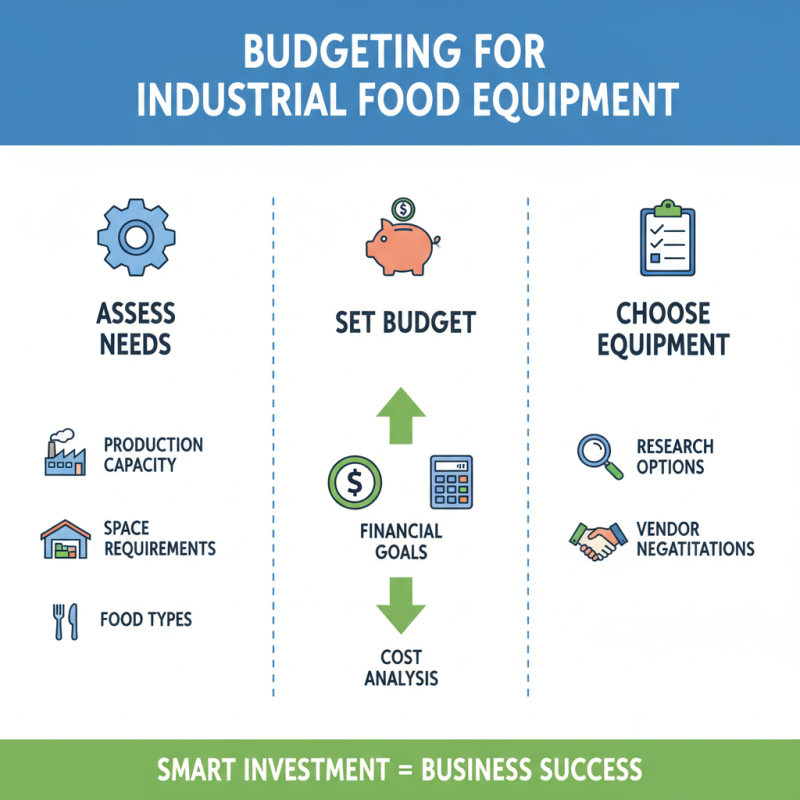

Budgeting for your industrial food equipment purchase is a critical step that can impact the success of your business. Before making any decisions, it's essential to assess your specific needs and the type of equipment that would best suit your operations. Consider factors such as production capacity, space requirements, and the types of food products you'll be handling. Establishing a clear understanding of your goals will help you identify the right equipment within your budget.

When it comes to budgeting, a good tip is to create a detailed list of all the essential features and capabilities you need from the equipment. This will help narrow down your options and prevent overspending on unnecessary features. Additionally, don't forget to factor in ongoing costs like maintenance, energy consumption, and potential upgrades in your financial planning. It's not only about the initial purchase price—being realistic about the total cost of ownership will ensure you stay within budget in the long run.

Another useful tip is to explore financing options available for industrial equipment purchases. Many suppliers offer leasing programs or financing plans that can spread out payments over time, making it easier for businesses to manage their cash flow. Additionally, researching second-hand equipment can yield significant savings while still meeting your operational needs. By being strategic and thorough in your budgeting process, you can make informed decisions that align with your business objectives.

Maintenance and Support Considerations for Equipment Longevity

When selecting industrial food equipment, maintenance and support should be a primary consideration to ensure the longevity of your investment. Performing regular maintenance not only keeps your equipment running smoothly but also helps prevent costly breakdowns that can disrupt operations. Schedule routine inspections, cleanings, and parts replacement to maximize the lifespan of your machinery.

**Tips:** Create a maintenance checklist tailored to your equipment type, including specific tasks and timelines. Training employees on proper handling and upkeep procedures can enhance care and prevent misuse.

Additionally, consider the availability of support services when making your purchase. Opt for suppliers who offer reliable customer service, including installation assistance and troubleshooting support. This will help you resolve any issues quickly and maintain operational efficiency.

**Tips:** Research service agreements that provide ongoing support, including emergency repair options. Establish a communication plan with your supplier to ensure prompt assistance when needed.

Maintenance and Support Considerations for Industrial Food Equipment

Related Posts

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

How to Choose the Right Dog Food Manufacturing Equipment for Your Business

-

2025 How to Choose the Best Stainless Steel Conveyors for Your Business

-

Top Benefits of Using Steel Conveyor Belts in Industrial Applications

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One