How to Choose the Right Industrial Food Processing Equipment for Your Business?

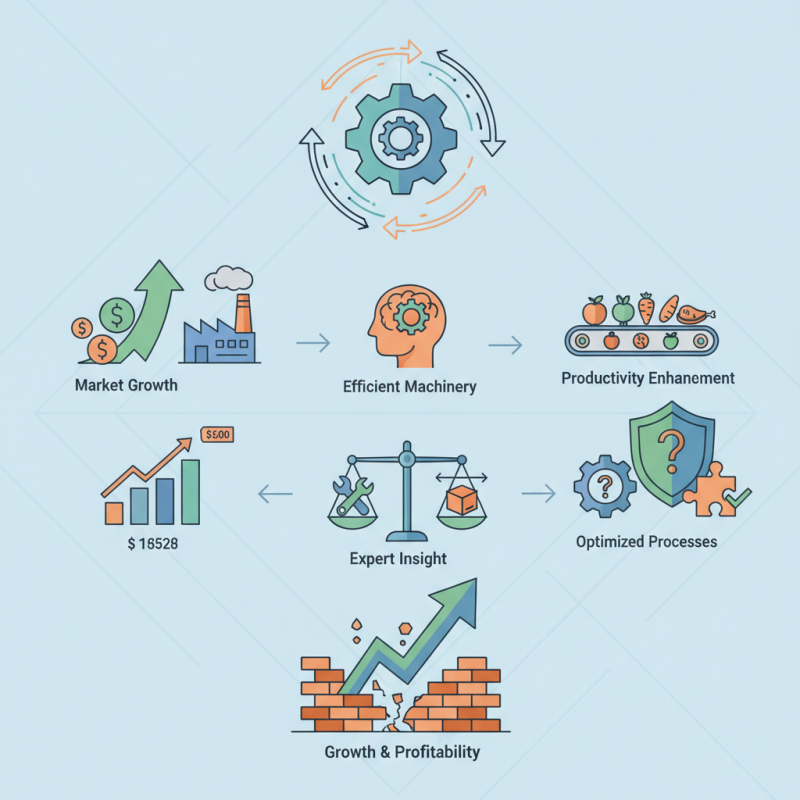

Choosing the right industrial food processing equipment is crucial for businesses in the food industry. According to a report by Research and Markets, the global market for industrial food processing equipment is expected to reach $60 billion by 2025. This growth highlights the increasing importance of efficient machinery for food production.

John Smith, an expert in food processing technology, states, “Selecting the right equipment can dramatically improve operational efficiency.” His insight emphasizes the need for careful evaluation of processing needs and available equipment. However, many businesses often overlook critical factors, such as scalability and maintenance requirements, leading to costly inefficiencies.

Investing in the appropriate industrial food processing equipment can enhance productivity. Yet, the decision-making process is not always straightforward. Not all businesses fully understand their specific requirements. They may settle for equipment that does not optimize their unique production processes. This oversight can hinder growth and profitability in a competitive market.

Understanding Your Business Needs for Food Processing Equipment

When it comes to food processing equipment, understanding your business needs is crucial. Each business has unique requirements that directly affect equipment choice.

Consider the type of food you process. Fresh produce, dairy, or meat all require different systems. Assessment of your product lines is a necessary first step.

Next, think about production capacity. How much food do you intend to process daily? Equipment size and efficiency play key roles here. Some might choose a smaller scale for local markets while others eye large-scale operations. Each choice comes with trade-offs.

Additionally, evaluate your workspace layout. Equipment must fit efficiently into your production area.

Don’t overlook budget constraints. Quality equipment can be costly, but cutting corners might lead to higher maintenance costs later. Sometimes, cheaper options lead to inefficiency. It’s a complex balance of costs versus long-term benefits. Regularly reassessing your needs is important; growing businesses may outgrow their initial choices quickly. Flexibility can be essential for future expansion.

Evaluating Different Types of Food Processing Equipment Available

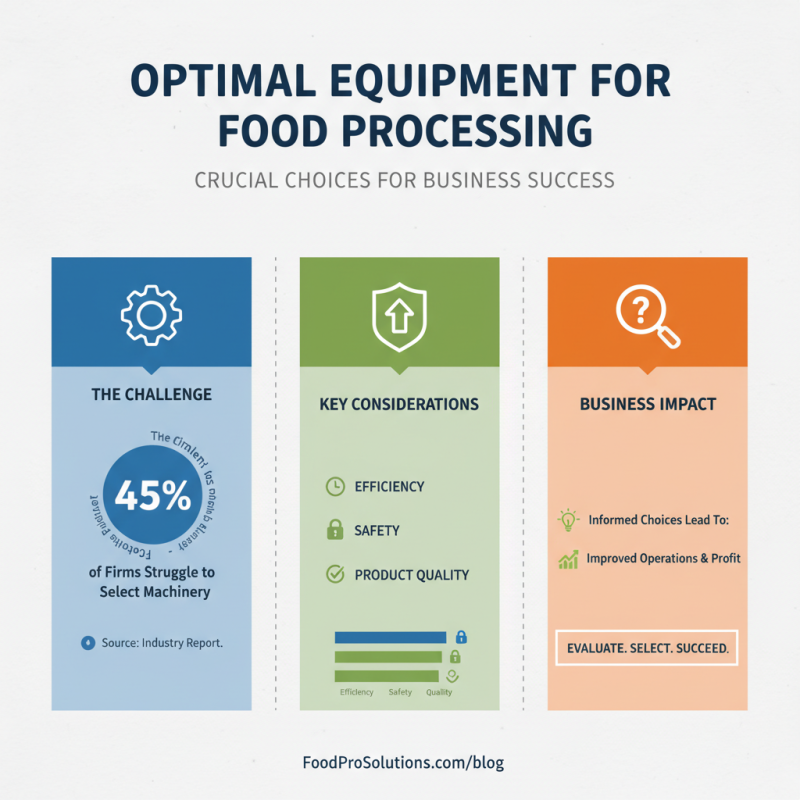

Choosing the right equipment can be daunting for food processing businesses. Various types of food processing machinery cater to different needs, making evaluation essential. A recent industry report claims that over 45% of food production firms struggle to select appropriate machinery. It highlights the importance of understanding how equipment impacts efficiency, safety, and product quality.

When examining the available types, consider key factors like capacity, maintenance, and adaptability. For example, automated systems can significantly enhance output. However, they often come with a heftier price tag. A survey showed that nearly 30% of small-scale processors reported dissatisfaction due to misalignment between equipment capabilities and business goals. This suggests that thorough assessments are necessary before making purchases.

Energy efficiency is another critical factor. According to industry analysis, energy-efficient machines can reduce energy costs by up to 25%. Finding the right balance between upfront costs and long-term savings can be tough. Not all equipment transitions smoothly into existing operations. Reviewing user experiences reveals that mismatches in workflow can lead to operational disruptions. Therefore, businesses need to engage in careful evaluation of all available options.

Key Features to Consider When Choosing Food Processing Machinery

Choosing the right industrial food processing equipment is crucial for any food business. When evaluating machinery, size and capacity matter significantly. Ensure the equipment fits your production scale. For instance, if your output changes frequently, consider adjustable equipment. Not every solution fits every need, so flexibility is key.

Another vital feature is energy efficiency. Upgrading to modern machinery can save on utility costs. It's important to weigh the initial investment against long-term savings. Maintenance requirements should be clear. Some machines demand more care than others. This can lead to unexpected downtime. Select equipment that aligns with your team's expertise. Not all employees can jump into complex operations without training.

Finally, consider the support from suppliers. Good customer service can save you time and frustration. If issues arise, quick support can be a lifesaver. Look for parts availability too. If machines break down, waiting for parts can hamper production. These details are often overlooked, but they can impact your bottom line. Take the time to reflect on what features will truly benefit your operation.

Key Features to Consider When Choosing Food Processing Equipment

Assessing Safety and Compliance Standards in Food Equipment Selection

In the industrial food processing sector, safety and compliance are paramount. When selecting equipment, ensure it meets local safety regulations. This avoids potential hazards. Equipment should be easy to clean to prevent contamination. Think about materials used. Stainless steel is often preferred for its durability and safety.

Tips: Check for certifications. Look for equipment that complies with FDA and USDA standards. These certifications assure a level of safety that’s critical in food processing. Ask suppliers about cleaning protocols. Proper hygiene practices can save you from costly recalls later.

Evaluate the equipment's design. It should minimize risks of accidents or injuries. For example, guards and emergency stops are essential features. Inadequate safety measures can lead to workplace injuries. Reflect on the layout of your facility, too. Space constraints can impact safety. An efficient layout considers worker movement and equipment access.

Budgeting and Cost Analysis for Industrial Food Processing Investments

Budgeting for industrial food processing investments is critical. Equipment costs can vary significantly. In 2022, the global food processing machinery market was valued at around $35 billion. It is projected to grow by 6% annually. Businesses must consider these costs carefully.

When planning your budget, account for both upfront and ongoing expenses. Many equipment pieces require maintenance and energy. For instance, energy costs can contribute up to 40% of a facility's operating budget. Companies often overlook this aspect, resulting in financial stress. A detailed cost analysis can help in avoiding unexpected expenses.

Consider the expected return on investment (ROI). A well-chosen machine can improve efficiency and product quality. Studies show that companies investing wisely see a 20% increase in productivity within the first year. Yet, the wrong choice can lead to budget overruns and diminished returns. Conduct thorough research and seek expert opinions before making decisions. Balancing cost with quality is essential in the food processing industry.

How to Choose the Right Industrial Food Processing Equipment for Your Business? - Budgeting and Cost Analysis for Industrial Food Processing Investments

| Equipment Type | Estimated Cost ($) | Maintenance Cost (Annual) ($) | Energy Consumption (kWh/year) | Production Capacity (units/hour) |

|---|---|---|---|---|

| Mixer | 5,000 | 500 | 2,000 | 300 |

| Conveyor System | 10,000 | 800 | 1,500 | 600 |

| Packaging Machine | 15,000 | 1,200 | 3,500 | 1,200 |

| Cooking Equipment | 20,000 | 1,500 | 4,000 | 250 |

| Chilling System | 12,000 | 700 | 2,000 | 400 |

Related Posts

-

2025 How to Choose the Right Screw Conveyor Auger for Your Needs

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time

-

Why Are Belt Conveyor Systems Essential for Modern Manufacturing Efficiency

-

How to Choose the Best Commercial Meat Grinder for Your Business Needs

-

Best 10 Industrial Meat Grinders for Efficient Meat Processing

-

How to Choose the Best Industrial Food Grinder Machine for Your Business