2025 How to Choose the Right Screw Conveyor Auger for Your Needs

When it comes to selecting the right screw conveyor auger for your specific needs, the importance of making an informed decision cannot be overstated. Jonathon Harris, a leading expert in material handling solutions, emphasizes, “Choosing the right screw conveyor auger is crucial to ensure efficient material transport and reduce operational costs.” This highlights the central role that a well-suited auger plays in enhancing productivity and optimizing processes within various industries.

With a multitude of options available, understanding the characteristics and capabilities of different screw conveyor augers becomes imperative. Factors such as material type, flow rate, and environment must all be considered to ensure the selected auger effectively meets the operational requirements. Making these considerations can prevent costly mistakes and contribute to a more streamlined material handling system.

In the following sections, we will explore essential aspects to keep in mind when choosing a screw conveyor auger, ensuring you make the right investment for your business's distinct needs. Whether you are an industry veteran or new to the field, having the right knowledge will empower you to select the most suitable solution for your material handling challenges.

Understanding the Basics of Screw Conveyor Augers

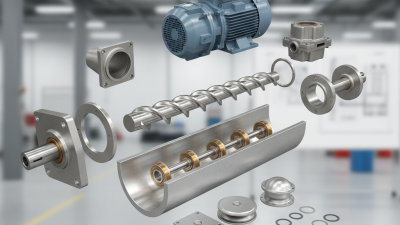

Screw conveyor augers are essential components in various industries for the efficient movement of bulk materials. Understanding the basics of these devices is critical when selecting the right auger for your specific needs. A screw conveyor consists of a helical screw blade that rotates within a tubular or trough-like casing. As the screw rotates, it moves the material along the length of the conveyor, making it ideal for transferring materials over short distances or through restricted spaces.

When choosing a screw conveyor auger, it is vital to consider factors such as the type of material being conveyed, its flow characteristics, and the required throughput rate. For instance, free-flowing materials differ significantly in handling compared to cohesive or sticky materials.

Additionally, the auger’s diameter, pitch, and rotation speed can influence the efficiency and effectiveness of material transport, making it necessary to match these specifications with the operational requirements of your application. By understanding these fundamentals, businesses can enhance their materials handling processes and optimize their production efficiency.

Identifying Your Material Handling Requirements

When selecting the right screw conveyor auger for your material handling requirements, understanding the specific characteristics of the materials you will be transporting is crucial. The physical properties of the materials, including their density, moisture content, and particle size distribution, can significantly impact the efficiency and effectiveness of a screw conveyor system. According to the Conveyor Equipment Manufacturers Association (CEMA), bulk density can vary widely, with some materials measuring as little as 4 lbs/ft³ to over 100 lbs/ft³. Analyzing these factors helps in determining the appropriate screw conveyor configuration that will optimize performance.

Another critical consideration is the flow characteristics of the materials. For instance, cohesive or sticky materials may require a different screw design compared to free-flowing materials. The CEMA’s guidelines suggest that understanding the angle of repose and friction coefficient of your materials can aid in selecting the right screw diameter and pitch. Additionally, specific applications may need to accommodate factors like temperature and corrosiveness, guiding the choice of materials used in the conveyor itself. Data from industry reports indicate that a well-matched screw conveyor auger can enhance throughput by as much as 25%, reflecting the importance of aligning conveyor specifications with your unique handling requirements.

2025 How to Choose the Right Screw Conveyor Auger for Your Needs - Identifying Your Material Handling Requirements

| Material Type | Density (lb/ft³) | Moisture Content (%) | Screw Diameter (inches) | Length (feet) | Capacity (tons/hour) |

|---|---|---|---|---|---|

| Cement | 100 | 0.5 | 12 | 20 | 40 |

| Grains | 50 | 12 | 10 | 30 | 25 |

| Sand | 90 | 2 | 14 | 25 | 35 |

| Coal | 60 | 5 | 16 | 15 | 30 |

| Sugar | 80 | 2 | 12 | 20 | 20 |

Evaluating Different Auger Designs and Configurations

When choosing the right screw conveyor auger for your needs, evaluating different auger designs and configurations is crucial. Auger designs can vary widely, impacting their efficiency, capacity, and adaptability to specific materials or operational environments. For instance, a helix with a larger diameter may be ideal for moving bulkier materials, while a smaller, tighter helix is more suitable for finer powders. Additionally, the pitch of the screw is vital; a steep pitch can facilitate faster material transfer, but careful consideration must be given to potential increases in friction and wear.

Another important aspect to consider is the arrangement and orientation of the auger. Horizontal augers are commonly used for transporting materials over short distances, while inclined or vertical configurations can effectively move materials up to a higher elevation. Moreover, enclosed or open designs serve different needs; while enclosed augers prevent material loss and contamination, open designs may be more accessible for maintenance. By thoroughly assessing these various auger designs and configurations, you can ensure that your selected screw conveyor auger meets the specific requirements of your application, improving operational efficiency and material handling.

2025 Screw Conveyor Auger Designs Comparison

Considering Size, Speed, and Capacity Factors

When selecting the right screw conveyor auger for your operational needs, understanding the factors of size, speed, and capacity is crucial. The size of the auger is determined not only by the dimensions of the material being conveyed but also by the space available in your facility. A well-sized screw conveyor will maximize efficiency and minimize material handling issues. Typically, the diameter and length of the auger should align with both the flow rate requirements and the characteristics of the materials, ensuring optimal performance without unnecessary bottlenecks.

Speed, often overlooked, plays a significant role in the overall efficacy of your screw conveyor system. The rotational speed of the auger impacts how quickly materials are moved and can also influence the mixing and homogenizing processes. It is essential to find a balance; too high a speed may lead to materials being damaged or exhibiting poor flow characteristics, while too low a speed can cause delays and decreased productivity. Additionally, evaluating the capacity of the screw conveyor is vital. This measurement reflects the volumetric space that the auger can handle efficiently, often calculated based on the material's bulk density and the auger’s fill level. Ensuring that the chosen auger can handle your required capacity is fundamental for maintaining consistent production flow.

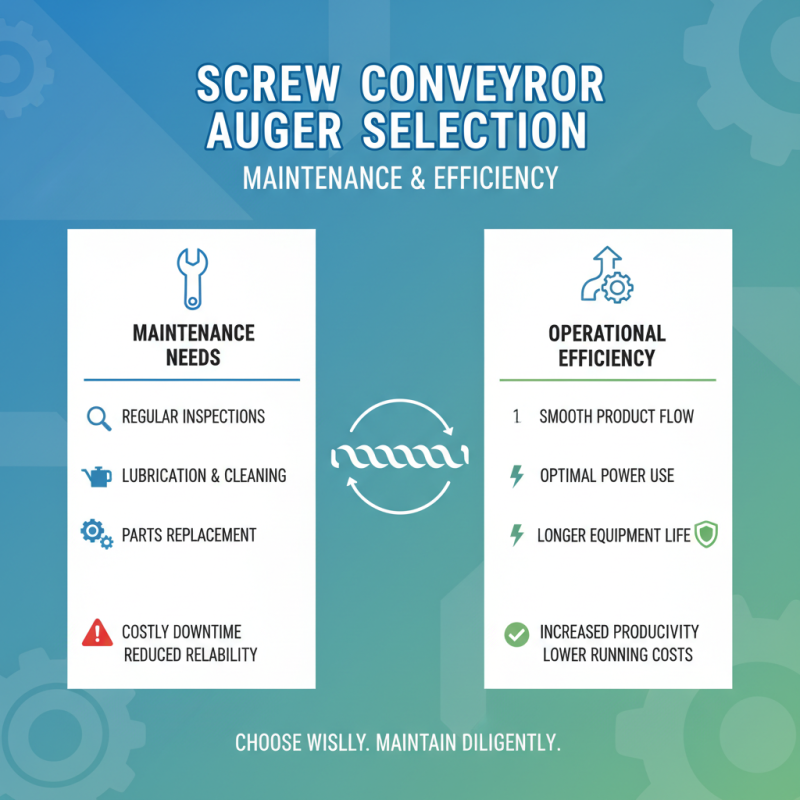

Assessing Maintenance Needs and Operational Efficiency

When selecting a screw conveyor auger, assessing maintenance needs and operational efficiency is paramount. Choosing the right equipment involves not just the initial purchase but an understanding of how well it will perform in the long run. Efficient operation can be hindered by improper maintenance, leading to costly downtimes and inefficient production processes. Regular inspections and maintenance routines are vital in ensuring that the auger operates smoothly and reliably.

Tips for maintaining your screw conveyor include scheduling regular cleaning to prevent material buildup that can impede functionality. Lubrication of moving parts is crucial to minimize friction and wear, enhancing the durability of the auger. Additionally, keep an eye on potential wear areas, such as the flights and trough, and replace components as needed to avoid larger issues down the line.

Operational efficiency can also be improved by adjusting the speed and loading levels of the screw conveyor according to the specific materials being handled. Understanding the characteristics of the material, such as flowability and density, will allow you to optimize the auger's performance. Ensuring that these factors are aligned with the operational parameters will lead to a more efficient process and extended equipment lifespan.

Related Posts

-

Why Are Belt Conveyor Systems Essential for Modern Manufacturing Efficiency

-

How to Choose the Best Commercial Meat Grinder for Your Business Needs

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling

-

7 Best Metal Detectors for Conveyor Belts to Ensure Quality Control in 2023

-

Top 10 Essential Screw Conveyor Parts You Need to Know for Optimal Performance