What is Dog Food Manufacturing Equipment? Essential Tools for Pet Food Production

In the ever-evolving pet food industry, the efficiency and effectiveness of production largely hinge on the quality of dog food manufacturing equipment. According to Dr. Sarah Thompson, a leading expert in pet nutrition and food technologies, "Investing in the right dog food manufacturing equipment is crucial for ensuring product safety and meeting consumer demand." The intricate process of creating high-quality dog food requires specialized machinery designed to handle various stages of manufacturing, from ingredient preparation to packaging.

As pet owners become increasingly discerning about their dog's dietary needs, manufacturers are under pressure to innovate and improve their production lines. The significance of advanced dog food manufacturing equipment cannot be overstated, as it not only enhances production efficiency but also contributes to the overall quality of the final product. With the right tools, manufacturers can achieve consistent formulations, maintain rigorous safety standards, and ultimately support the health and well-being of pets.

As we delve further into the essential tools used in the production of dog food, we will explore the various types of equipment available, their specific functions, and how they collectively play a pivotal role in meeting the demands of a competitive market. Understanding these components is vital for anyone involved in pet food production, as they form the backbone of a successful manufacturing operation.

Understanding Dog Food Manufacturing Equipment

Dog food manufacturing equipment plays a crucial role in the production of high-quality pet food, ensuring that all nutritional standards are met while maintaining efficiency in operations. Essential tools include mixers, extruders, dryers, and packaging machines, each serving a specific purpose in the complex manufacturing process. According to industry reports, the global pet food market is expected to reach approximately $113 billion by 2026, with an increasing demand for premium products that necessitate advanced manufacturing equipment. This shift highlights the importance of cutting-edge technology and machinery in meeting the evolving preferences of pet owners.

In addition to enhancing the quality and consistency of the final product, dog food manufacturing equipment significantly affects production timelines and costs. For instance, high-capacity extruders can handle diverse ingredients and formulations, allowing manufacturers to quickly adapt to market trends. A report from the Pet Food Industry Association notes that automation in manufacturing can lead to a reduction in labor costs by up to 20%, further underscoring the importance of investing in efficient equipment. As companies look to optimize their production processes, understanding the capabilities and functions of various manufacturing tools will be essential for success in the competitive pet food landscape.

Key Components of Pet Food Production Machinery

Pet food production machinery encompasses several key components that are essential for creating high-quality dog food. At the forefront is the mixer, which blends dry and wet ingredients uniformly to ensure a consistent nutritional profile. Mixers can come in various designs, including paddle and ribbon types, each serving the purpose of effectively combining protein sources, grains, vitamins, and minerals required for complete pet nutrition. The precision of the mixer directly affects the overall quality of the final product, making it a crucial element in the manufacturing process.

Following the mixing stage, the extrusion process plays a vital role in shaping and cooking the dog food. Extruders utilize high heat and pressure to transform the mixture into palatable kibble. This method not only enhances the flavor and aroma of pet food but also ensures that it is digestible and safe for consumption. Furthermore, specialized equipment such as dryers and coolers are employed after extrusion to remove moisture, extending the shelf life of the product. The incorporation of these essential tools in pet food production machinery illustrates the complexity and precision required to manufacture nutritious and appealing dog food for pet owners.

What is Dog Food Manufacturing Equipment? Essential Tools for Pet Food Production - Key Components of Pet Food Production Machinery

| Component | Function | Material Type | Maintenance Frequency |

|---|---|---|---|

| Mixer | Blends ingredients uniformly | Stainless Steel | Weekly |

| Extruder | Shapes and cooks the dog food | Alloy Steel | Monthly |

| Dryer | Removes moisture from pellets | Galvanized Steel | Monthly |

| Cooler | Reduces temperature of pellets | Stainless Steel | Bi-Monthly |

| Packaging Machine | Packages finished dog food | Plastic and Metal | Weekly |

Types of Dog Food Manufacturing Equipment Available

When it comes to dog food manufacturing, understanding the types of equipment available is essential for efficient and high-quality production. The pet food industry employs various machines designed for specific tasks, ensuring the dog food is both nutritious and palatable.

Key types of equipment include mixing machines, which uniformly blend the ingredients; extruders, which form kibble through cooking and shaping; and dryers, which remove moisture to extend shelf life. Additionally, packaging equipment is crucial for sealing and protecting the product, ensuring it reaches consumers in optimal condition.

Tips: Always ensure that your equipment is maintained and cleaned regularly to prevent cross-contamination and ensure safety. Also, consider the scale of your production when choosing equipment; investing in larger machines may reduce costs in the long run for high-volume production.

Beyond these essentials, additional tools like fillers, slicers, and grinders play significant roles in the production line. Fillers help in precisely portioning the food into packaging, while slicers are critical for creating specific shapes in soft dog foods. Grinders are often used to prepare meat and other ingredients to the right consistency. Understanding the diverse functionalities of these tools will not only improve production efficiency but also enhance product quality, making it a vital aspect for any budding pet food manufacturer.

Tips: Research the latest technologies in pet food manufacturing equipment, as advancements can lead to better efficiency and improved product quality, keeping you competitive in a growing market.

The Role of Quality Control in Pet Food Production

Quality control plays a crucial role in pet food production, ensuring that the final products meet safety standards and nutritional specifications. In the manufacturing process, quality control starts from the selection of raw materials. Manufacturers must rigorously check the ingredients for purity and nutritional value, as these factors directly impact the health and wellbeing of the pets consuming the food. Every batch of ingredients undergoes testing to avoid contamination and detect any harmful substances. This foundational step sets the stage for maintaining high quality throughout the production process.

As the manufacturing progresses, various quality control measures are employed to monitor the equipment and the processes in place. This includes regular inspections of production lines, monitoring cooking temperatures, and ensuring proper mixing of ingredients to achieve consistency in the final product. These measures help in identifying potential issues early in the production cycle, reducing waste and ensuring that the food produced is safe and nutritionally adequate. Additionally, the implementation of stringent testing protocols at the end of the production process guarantees that every product complies with established quality standards before it reaches consumers. The overall commitment to quality control not only safeguards pet health but also fosters trust between manufacturers and pet owners, ultimately contributing to the success of pet food brands in a competitive market.

Maintaining and Upgrading Dog Food Manufacturing Equipment

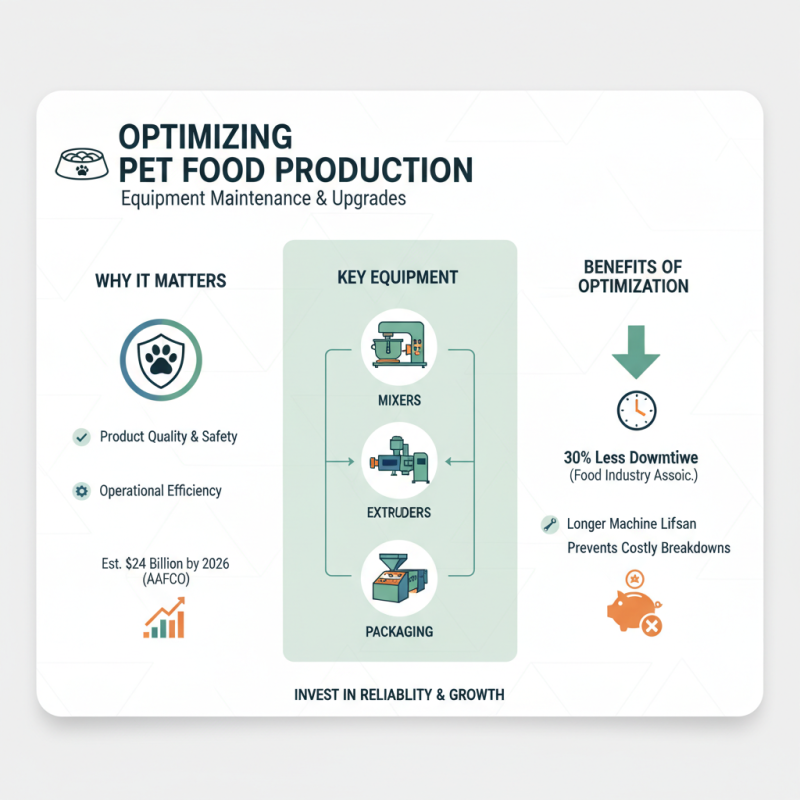

Maintaining and upgrading dog food manufacturing equipment is crucial for ensuring product quality, safety, and operational efficiency. According to a report from the Association of American Feed Control Officials (AAFCO), the pet food industry is projected to reach $24 billion in revenue by 2026, underlining the importance of utilizing optimized manufacturing processes. Regular maintenance not only helps prevent costly breakdowns but also extends the life of the machinery. This includes routine checks on mixers, extruders, and packaging machines, which are the backbone of any pet food production facility. An effective maintenance schedule can lead to a decrease in downtime by approximately 30%, as reported by the Food Industry Association.

Upgrading equipment is another vital aspect of maintaining competitiveness in the dog food manufacturing landscape. With advancements in technology, facilities can implement automation and better energy-efficient systems that can enhance production capacities. According to a recent industry survey, companies that invested in modern equipment saw a 25% increase in production efficiency. Retrofitting existing machines with the latest technologies ensures compliance with health standards and can significantly reduce waste and environmental impact. Adopting these upgrades not only meets the increasing consumer demand for high-quality pet foods but also positions manufacturers to keep pace with the evolving industry regulations and trends.

Related Posts

-

The Ultimate Guide to Dog Food Manufacturing Equipment in 2025 Top Trends

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

2025 Top Commercial Meat Grinders with Industry Leading Performance and Durability

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling